9 May 2025

How Latin American manufacturers can future-proof their spare parts strategy

The manufacturing industry is no stranger to disruption, but the lasting impact of tariffs is now making it more expensive and more complicated to source spare parts for machinery.

The resurgence of U.S. tariffs under President Donald Trump's administration has introduced significant challenges for Latin American manufacturers. These tariffs, particularly the 25% duties on imports from Mexico and Canada and up to 145% on Chinese goods, have disrupted supply chains, increased costs, and necessitated strategic shifts in sourcing and logistics. The U.S. has slapped tariffs on over $400 billion worth of imported goods (World Bank, 2024) — and that includes critical spare part components used across dozens of industries.

As these tariffs continue, manufacturers are seeing rising costs ripple across their operations. For spare parts that are already complex to source and often time-sensitive, the added expense can significantly impact margins, operational agility, and overall plant performance. Fortunately, there’s a smarter way forward: by rethinking your sourcing strategy, collaborating with the right procurement partners, and safeguarding your margins.

The Real Cost Isn’t Just the Price, it’s the Downtime.

Previously, Latin American manufacturers could source the components they required on demand, primarily from suppliers based in the United States or China.

Today, however, the landscape has changed significantly. Companies are now encountering:

- Substantial cost increases, with prices for critical parts rising by 15–30%.

- Extended delivery times, often delayed by several weeks.

- Heightened supply chain risks, including supplier instability and order cancellations.

Delays in sourcing or shipping a single part can lead to costly downtime and missed deadlines. Now, with increased import costs and longer lead times, the risks are even higher.

This is why manufacturers are shifting away from fragmented supplier networks and embracing a more strategic, single supplier consolidated approach to spare parts sourcing and procurement.

Inventory Optimisation: More Than Just Stock Control

In this environment, inventory optimisation is no longer optional, it is critical.

Manufacturers require greater visibility into current inventory levels, future demand, and timing requirements to ensure operational efficiency and continuity. Holding too much stock ties up capital. Holding too little leads to delays and downtime. The key is right-sizing inventory with smarter planning, using reliable data and forecasting tools to inform decisions.

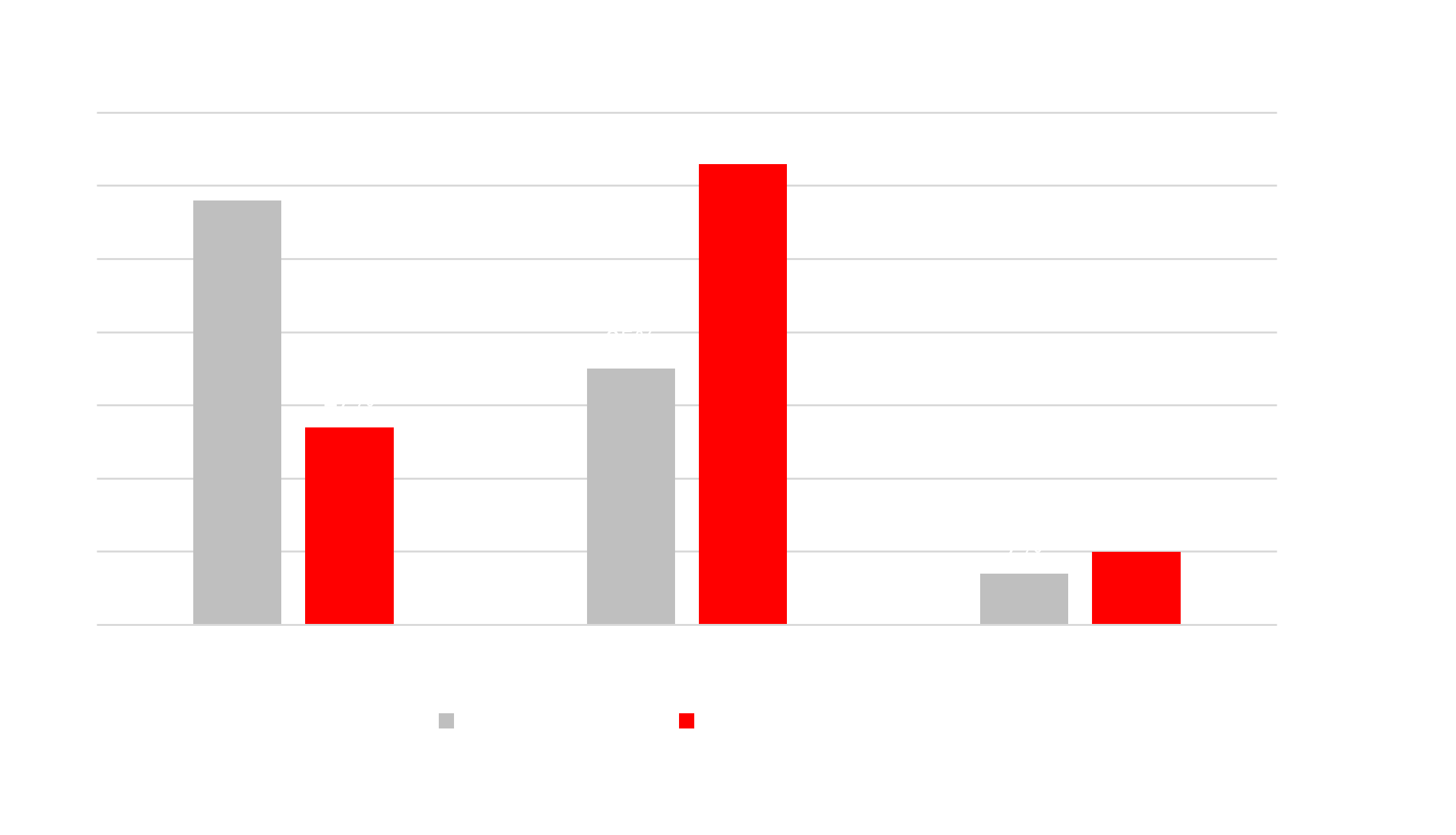

Recent shift in inventory management:

Partnering with an experienced MRO provider can unlock this capability. With access to comprehensive procurement data, usage trends, and supplier performance metrics, businesses can take a proactive approach to managing their spare parts inventory.

Make Smarter Decisions with Better Insights

A modern spare parts strategy requires more than just consolidating vendors. It means leveraging data and insights to make faster, better decisions before problems arise. Manufacturers that invest in integrated systems and supplier partnerships gain real-time visibility into their supply chain and can act quickly when market conditions change.

That includes:

- Forecasting future demand based on historical usage.

- Identifying high-risk parts with long lead times

- Planning for seasonal or production-based fluctuations

- Evaluating supplier reliability and cost-effectiveness

How Entec International Helps Manufacturers Stay Ahead

We deliver integrated MRO and spare parts solutions that help manufacturers build more resilient, cost-effective operations. By consolidating your supplier network through Entec, you can:

- Reduce the cost and complexity of sourcing spare parts

- Optimise inventory levels across multiple sites

- Improve visibility into procurement data and trends

- Ensure fast, efficient response to urgent part needs

- Navigate tariffs and global supply chain disruptions with confidence.

As tariffs continue to reshape the manufacturing landscape, strategic spare parts planning is not just good practice, it is essential for long-term success.

Learn how we can support your spare parts strategy here

Latest News

-

15 Oct 2025

Cost Avoidance: Preserving Liquidity and Protecting ROCE in Manufacturing

-

1 Aug 2025

The strategic shift: Why African manufacturers are going global with MRO

-

4 Jul 2025

Our commitment to reducing our carbon footprint

-

9 May 2025

How Latin American manufacturers can future-proof their spare parts strategy

-

21 Feb 2025

Rethinking MRO Procurement: Moving Beyond the Status Quo

Get in touch

Have questions or need more information about our solutions? We’re here to help. Whether you’re looking to optimise your MRO processes or explore tailored services for your business, our team is ready to assist. Click below to reach out through our contact form, and one of our specialists will get back to you promptly. Let’s work together to achieve your operational goals.